Product Overview

Aluminium 5083 is known for exceptional performance in extreme environments. 5083 is highly resistant to attack by both seawater and industrial chemical environments. Alloy 5083 also retains exceptional strength after welding. It has the highest strength of the non-heat treatable alloys but is not recommended for use in temperatures over 65 °C.

Alloy Designations

Alloy 5083 also corresponds to GM41, A95083, AIMg 4.5 Mn, and Al-Mg 4.5 Mn 0.7.

Temper Types

The most common tempers for 5083 aluminum are O - Soft, H111 - Some work hardening imparted by shaping processes but less than required for H11 temper, and H32 - Work hardened by rolling then stabilized by low-temperature heat treatment to quarter hard.

Fabrication

▪ Solderability: Poor

▪ Weldability - Gas: Average

▪ Weldability - Arc: Excellent

▪ Weldability - Resistance: Excellent

▪ Brazability: Poor

▪ Workability - Cold: Average

▪ Machinability: Poor

TYPICAL APPLICATION

This material is used for pressure vessels, tip truck bodies, rail cars, shipbuilding, vehicle bodies, and mine skips & cages.

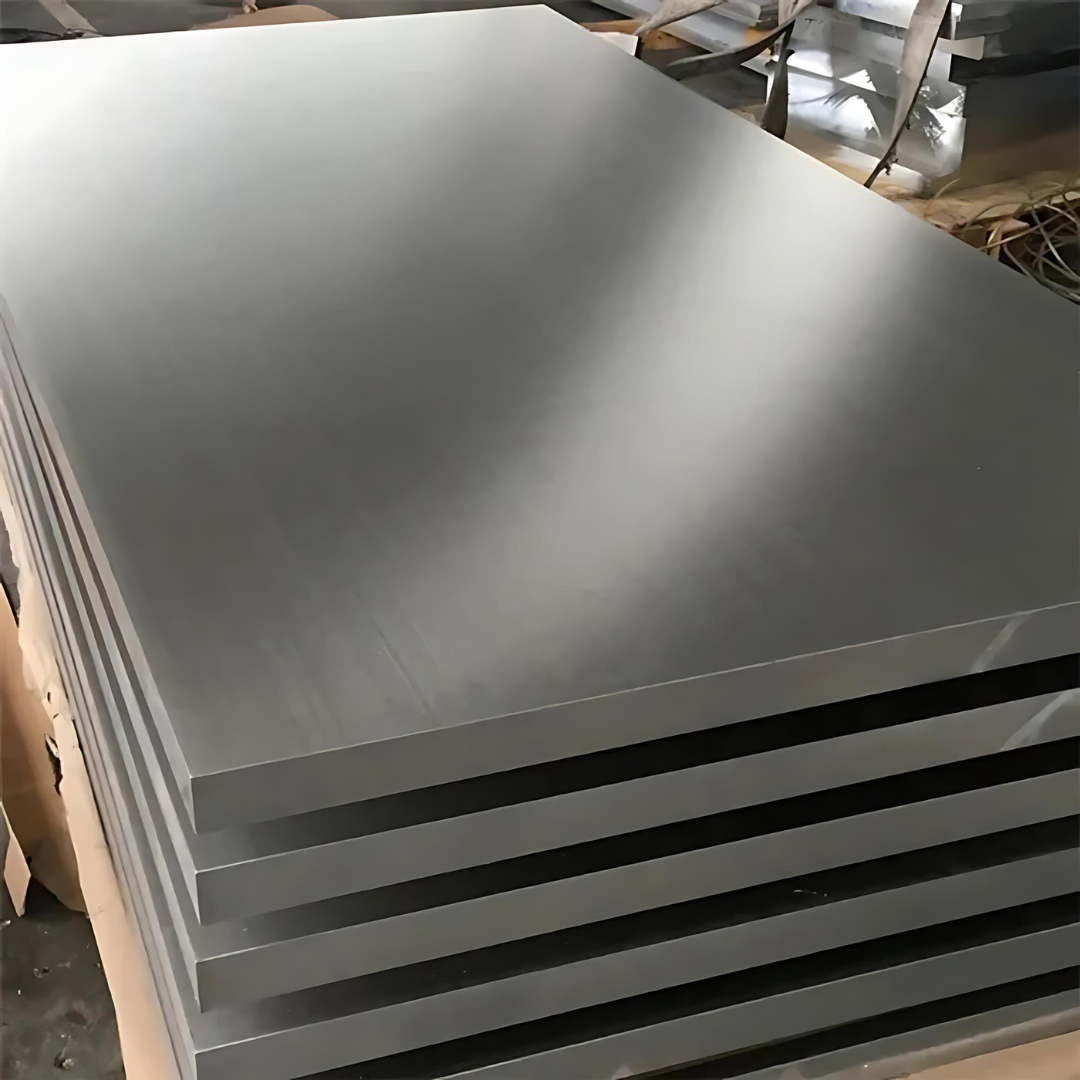

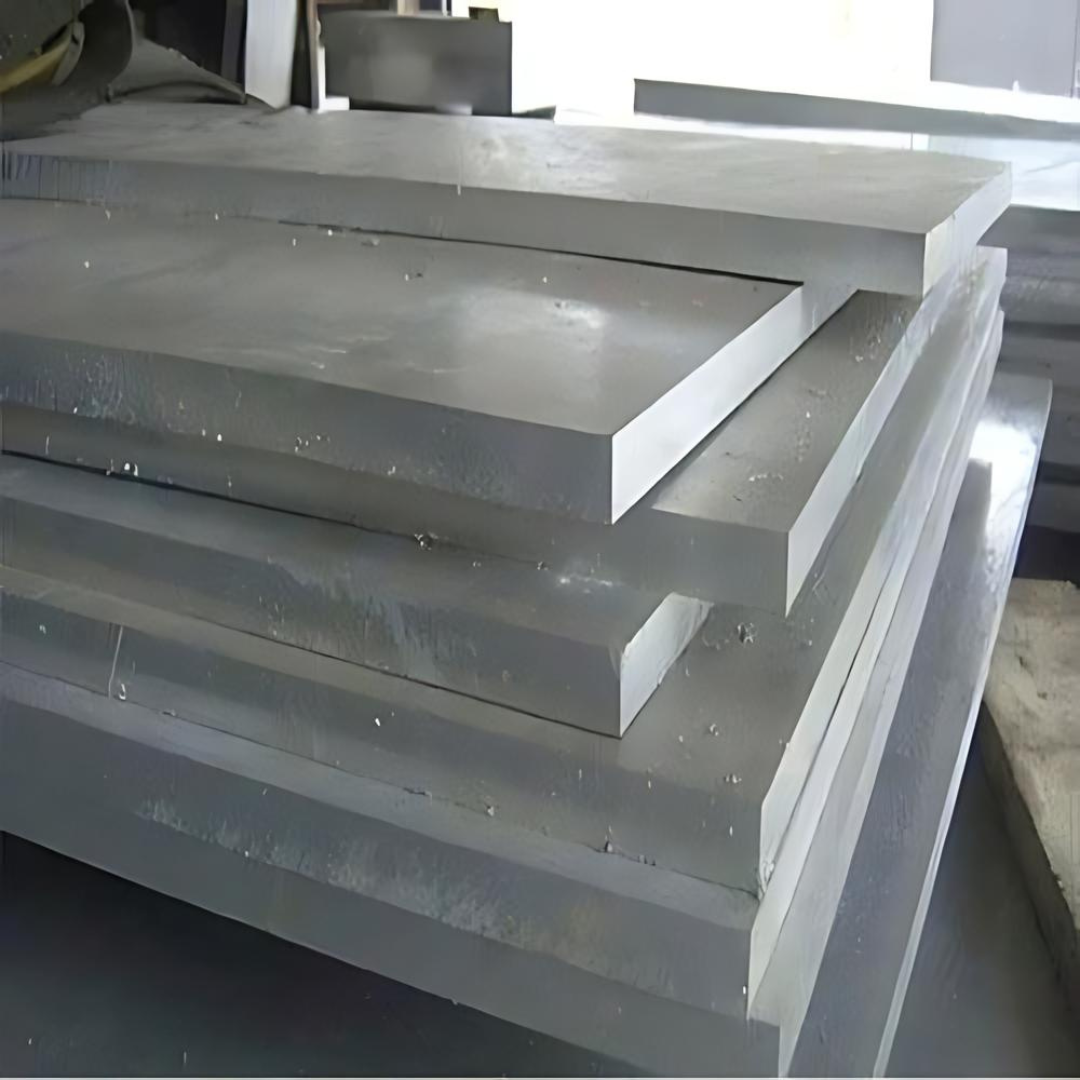

Supplied Forms

▪ Sheet

▪ Plate

Dimensions: 2mm to 10mm x 1500mm x 3000mm

AA1100 H14 Plates

3003 H14 Plates

5083 H111 Plates

5083 H116 Plates

6082 T6 Plates & Bars

7075 T6 Plates

5083 H111 Plates in the UAE: Properties, Applications, and Suppliers

There aren't many alloys as commonly specified and reliable as 5083 H111 when it comes to marine-grade aluminum. Choosing the appropriate material is crucial for engineers, project managers, and procurement professionals working in the UAE's rigorous industrial, maritime, and construction industries. Compared to other online resources, this comprehensive guide offers more in-depth analysis and useful information on 5083 H111 aluminum plates.

What is 5083 H111 Aluminum Plate? Understanding the Grade and Temper

You must first comprehend the meaning of the designation "5083 H111" in order to make an informed choice.

- 5083: This is the designation for the alloy. Magnesium (Mg) is the main alloying element in the 5xxx series. 5083 aluminum is well known for its outstanding weldability, remarkable strength, and outstanding resistance to corrosion, particularly in maritime settings.

- H111: This is the term for temper. The alloy has been strain-hardened, as indicated by the "H". In particular, the "111" indicates that the plate has undergone light annealing after being strain-hardened to a limited degree—less than what is necessary for an H11 temper. In contrast to the O (annealed) temper, this produces a final product that offers a superb balance of good formability and higher strength.

Key Chemical Composition of 5083 Aluminum

|

Element |

Content (%) |

Role & Impact |

|

Magnesium (Mg) |

4.0 - 4.9 |

Primary strengthener significantly enhances corrosion resistance. |

|

Manganese (Mn) |

0.4 - 1.0 |

Improves strength and workability. |

|

Chromium (Cr) |

0.05 - 0.25 |

Adds strength and improves resistance to stress corrosion cracking. |

|

Iron (Fe) |

≤ 0.40 |

Impurity, controlled to maintain performance. |

|

Silicon (Si) |

≤ 0.40 |

Impurity, controlled to maintain weldability. |

|

Copper (Cu) |

≤ 0.10 |

Impurity kept very low to maximize corrosion resistance. |

|

Zinc (Zn) |

≤ 0.25 |

Impurity. |

|

Titanium (Ti) |

≤ 0.15 |

Grain refiner. |

|

Aluminum (Al) |

Remainder |

Base metal. |

Superior Properties and Advantages of 5083 H111 Plates

Why is 5083 H111 the preferred material in the United Arab Emirates for so many severe applications? These are some of its most notable qualities:

- Exceptional Corrosion Resistance: Its most renowned quality is this. Because of its exceptional performance in saltwater environments, it is ideal for offshore projects and the UAE's extensive coastline. It is resistant to stress corrosion cracking, pitting, and crevice corrosion.

- High Strength-to-Weight Ratio: Compared to steel, 5083 H111 is around 35% lighter while yet providing exceptional strength. As a result, structures and vessels weigh less overall, which saves fuel and makes handling simpler.

- Excellent Weldability: Without suffering a major loss of characteristics in the heat-affected zone (HAZ), it can be easily welded using the most popular procedures (MIG, TIG). This makes manufacturing easier.

- Good Formability: The H111 temper is adaptable to a range of fabrication requirements since it permits moderate shaping and cold forming.

- High Impact Resistance: Even at extremely low temperatures, it maintains its strength and hardness, which is an advantageous characteristic for cryogenic applications such as LNG components.

- Non-Magnetic & Non-Sparking: For use in explosive situations or close to delicate electrical equipment, this is an essential safety element.

Top Applications of 5083 H111 Plates in the UAE Market

5083 H111's special qualities make it essential for several important sectors in the United Arab Emirates and the larger Gulf Cooperation Council.

- Marine & Shipbuilding: Decks, gangways, boat ramps, superstructures, and hull plating. It is unparalleled in its ability to withstand corrosion from saltwater.

- Construction & Architecture: Cladding, roofing, offshore platforms, bridge structural elements, and building facades close to the coast. Its small weight lessens the strain on buildings.

- Pressure Vessels & Chemical Industry: Because chemicals are non-reactive, they can be stored and transported using tanks, silos, and pipelines.

- Transportation: Weight reduction directly boosts payload capacity and fuel efficiency in railroad components, truck bodies, and trailer frames.

- Defense & Military: Applications needing armor and vehicle parts that are corrosion-resistant, strong, and lightweight.

- Cryogenic Applications: Parts for LNG facilities, a quickly expanding industry in the United Arab Emirates.

5083 H111 vs. Other Common Aluminum Grades: A Quick Comparison

|

Grade |

Primary Alloy |

Key Characteristics |

Best For |

|

5083 H111 |

Magnesium |

Marine-grade strength, excellent corrosion resistance, weldability. |

Shipbuilding, Marine, Offshore |

|

6061 T6 |

Magnesium & Silicon |

High strength, good machinability, less corrosion resistant than 5xxx. |

General fabrication, automotive, frames |

|

5052 H32 |

Magnesium |

Good formability, moderate strength, excellent corrosion resistance. |

Marine parts, electronic chassis, general sheet metal work |

|

3003 H14 |

Manganese |

It has very good formability and workability, moderate strength. |

Cooking utensils, chemical equipment, decorative trim |

Key Buying Considerations for 5083 H111 Plates in the UAE

To guarantee quality and value, consider these important considerations while obtaining 5083 H111 plates in Dubai, Abu Dhabi, or anywhere in the United Arab Emirates:

- Material Certification: Always demand a Certificate of Conformity (CoC) or Mill Test Certificate (MTC). This document ensures that the mechanical and chemical qualities fulfill ASTM B928 or EN 485 criteria and can be traced back to the heat/batch number.

- Supplier Reputation & Stock: Select a reputable metal provider with a solid reputation for dependability and quality. To prevent project delays, ask about their stock levels.

- Competitive Pricing: Obtain estimates from several vendors. Prices that look too good to be true should be avoided since they could be a sign of subpar or uncertified materials.

- Processing Services: Value-added services including drilling, edge finishing, plasma cutting, and cutting to size are provided by numerous leading UAE providers. In your fabrication process, this can result in considerable time and cost savings.

- Local Logistics: Consider the supplier's location and their capacity to manage logistics and delivery inside the main industrial zones of the United Arab Emirates (Jebel Ali, ICAD, DIP, etc.).

FAQ: 5083 H111 Aluminum Plates

Can 5083 aluminums be used for structural applications?

Of course. 5083 is frequently employed in structural applications, especially in maritime situations where its resistance to corrosion is a significant benefit. This is especially true of the H111 and H116/H321 tempers. International structural design codes are met by it.

How does the UAE's climate affect 5083 aluminum?

Many metals are severely corroded by the hot, muggy, and salty climate of the United Arab Emirates. Aluminum 5083 is specially designed to flourish in these circumstances. It creates a robust, shielding oxide layer that stops additional deterioration and guarantees long-term durability with little upkeep.

Is 5083 H111 plate easy to weld?

Indeed, it is regarded as one of the aluminum alloys that is easiest to weld. For optimal results and to keep the weld zone corrosion-resistant, use 5356 or 5183 filler wire.

What is the typical size and thickness range available?

A variety of 5083 H111 plates are available. Generally speaking, thickness might vary from 3 mm to 150 mm or more. Custom-cut sizes can frequently be obtained from vendors, while standard sheet and plate sizes are typically 1500 x 3000 mm or 2000 x 4000 mm.

Why is the H111 temper preferred over O-temper for many applications?

The H111 temper offers a considerable boost in strength while maintaining decent formability, whereas the O-temper is softer and more formable. For numerous fabrications where the item must maintain its shape under load, this makes it a "best of both worlds" choice.

Finding Reliable 5083 H111 Plate Suppliers in the UAE

The UAE is a major hub for metals and fabrication. When searching for a supplier, look for companies that:

- Have a proven track record supplying the marine, oil & gas, or construction industries.

- Carry stock from reputable international mills (e.g., from Europe, USA, or GCC).

- Provide full material traceability and certification.

- Offer technical support and processing services.

Keywords for your search:

- 5083 H111 plate suppliers UAE

- Marine grade aluminum plate Dubai

- Abu Dhabi 5083 aluminum stock

- Buy 5083 H111 plate Sharjah

- Aluminum sheet price UAE

- ASTM B928 plate distributor Jebel Ali

By choosing the right material and the right partner, you ensure the success, safety, and longevity of your project in the challenging and ambitious landscape of the United Arab Emirates.

Disclaimer

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as they become available.