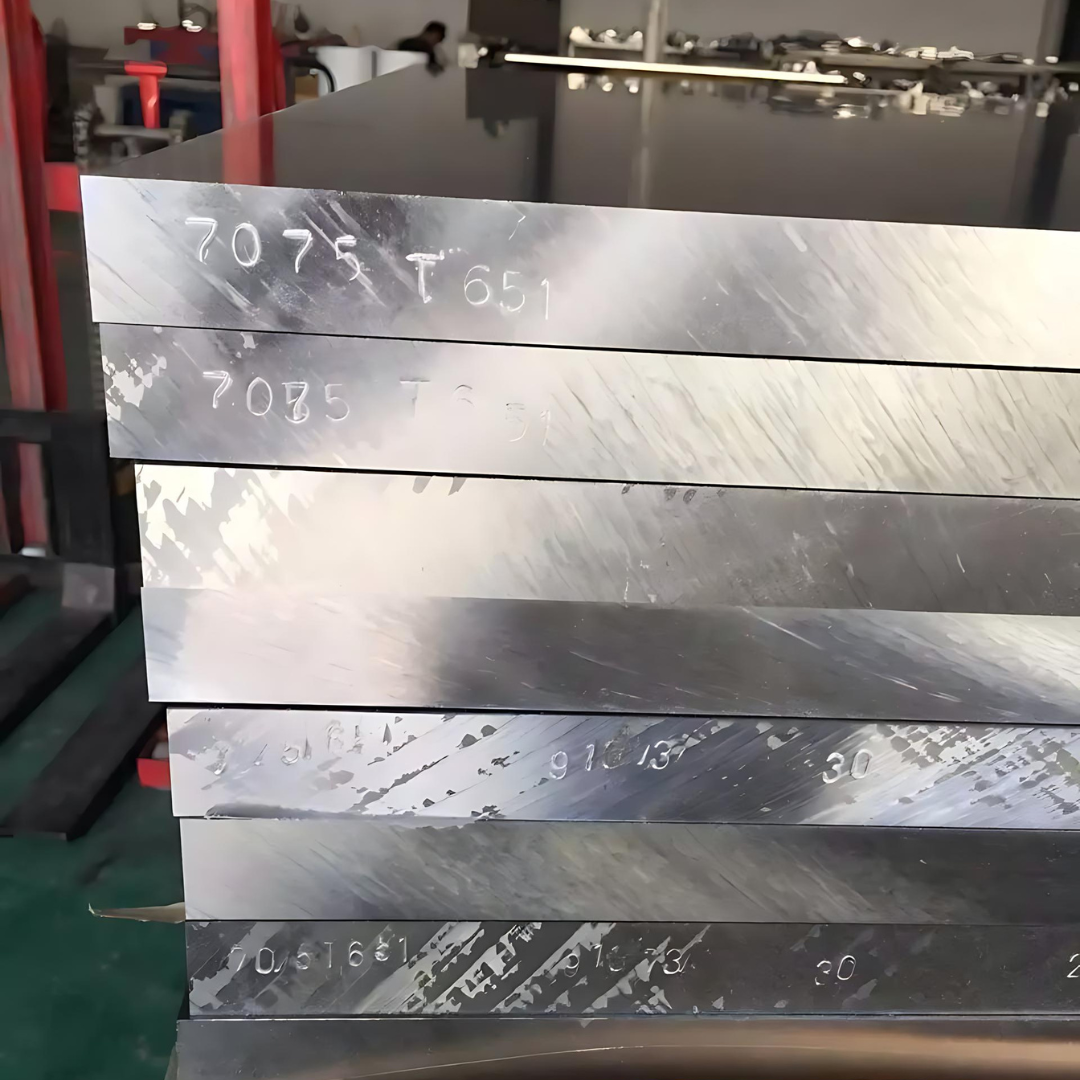

7075 T6 Plates

Product Overview

What is 7075-T6 aluminium?

With zinc as the dominant alloying element, the 7075 aluminum alloy (also known as aircraft aluminum or aerospace aluminum) was the first alloy of high strength composed by Al-Zn-Mg-Cu that was able to successfully combine the perks of the inclusion of chromium to develop high-stress-corrosion cracking resistance in sheet products. The composition of the 7075 aluminum alloy consists of 87.1 – 91.4% aluminum, while zinc is present in a concentration of 5 – 6%. It also contains 2.1 – 2.9% magnesium, 1.2 – 2%, and no more than 0.5% of silicon, titanium, chromium, iron, manganese, and other constituting metals.

The 7075-T6 aluminum is a 7075 aluminum alloy with a T6 temper, which is achieved by treating it with solution heat, homogenizing the 7075 casts at 450 °C for several hours, quenching, and then artificially aging it at 120 °C for 24 hours, which is around the time when it meets standard property requirements. This process guarantees achieving the peak strength of this alloy.

Application and Uses

The set of properties that 7075-T6 aluminum offers make it a solid choice for universal use in a variety of industries while remaining a favorite for the industries of aerospace, marine, and transportation due to its excellent strength-to-weight ratio. Other very common uses include top-line bicycle components, tool-making, gliders, meter gears, fuse parts, missile parts, worm gears, keys, regulating valve parts, and many other different commercial aircraft, aircraft fittings, and aerospace and defense equipment and components.

Conclusion

The 7075-T6 aluminum is the preferred choice for the aerospace, marine, and transportation industries, where low weight and high-stress resistance are crucial factors. However, its use is very popular in a variety of other industries, due to its well-balanced set of properties.

7075 T6 Aluminum Plates: Unleashing Premium Strength for UAE's Demanding Sectors

Standard aluminum alloys are inadequate in situations where exceptional strength, outstanding fatigue resistance, and unwavering performance are critical. The highest-grade option for the most demanding applications in the defense, aerospace, and high-performance engineering industries of the United Arab Emirates is 7075 T6 Aluminum Plate. Why 7075 T6 is the unchallenged leader in high-strength aluminum plates is examined in this comprehensive overview.

What is 7075 T6 Aluminum Plate? The "Aerospace-Grade" Powerhouse

The ultimate in high-strength aluminum alloys is 7075 T6. It is known for having strength like many steels while maintaining a low density, and it is a member of the 7000 series (aluminum-zinc alloys). The "T6" temper denotes that it has undergone artificial aging and solution heat treatment to attain its highest strength characteristics. When failure is not an option, this is the substance of choice.

7075 T6 Plate Technical Specifications: The Numbers Behind the Strength

For UAE engineers specifying materials for critical projects, here are the key properties that set 7075 T6 apart.

|

Property |

Details & Specifications for Critical UAE Applications |

|

Standard Plate Thickness |

0.5mm (shim) up to 150mm+ (3mm, 6mm, 10mm, 12mm, 20mm, 25mm, 30mm, 40mm, 50mm are commonly stocked in UAE) |

|

Standard Sheet Sizes |

1250x2500mm, 1500x3000mm, 2000x4000mm (Custom cutting is essential for this high-value material) |

|

Temper |

T6 (Solution Heat Treated and Artificially Aged) / T651 (Stress-Relieved Stretched) |

|

Yield Strength (Rp0.2) |

≥ 503 MPa |

|

Tensile Strength (Rm) |

572 MPa |

|

Elongation (A5) |

≈ 11% |

|

Brinell Hardness (HB) |

≈ 150 HB |

|

Chemical Composition |

Zinc (Zn): 5.1-6.1%, Magnesium (Mg): 2.1-2.9%, Copper (Cu): 1.2-2.0%, Chromium (Cr): 0.18-0.28% |

|

Common Finishes |

Mill Finish, Alodined (Chromate Conversion Coating), Anodized (Type II & III - Hardcoat) |

7075 T6 vs. 6061 T6 vs. 6082 T6: The Ultimate Aluminum Showdown in the UAE

This critical comparison helps UAE buyers select the right grade for their specific performance requirements.

|

Feature |

6061 T6 (General Purpose) |

6082 T6 (Structural) |

7075 T6 (Aerospace) |

Winner for High Stress |

|

Yield Strength |

240 MPa |

260 MPa |

503 MPa |

7075 T6 by 2x |

|

Tensile Strength |

290 MPa |

310 MPa |

572 MPa |

7075 T6 by 2x |

|

Strength-to-Weight |

Good |

Very Good |

Exceptional |

7075 T6 |

|

Corrosion Resistance |

Very Good |

Excellent |

Good (Requires protection) |

6082 T6 |

|

Weldability |

Excellent |

Excellent |

Poor (Not recommended) |

6061/6082 |

|

Machinability |

Good |

Good |

Excellent (Free-machining alloy) |

7075 T6 |

|

Fatigue Resistance |

Good |

Good |

Excellent |

7075 T6 |

|

Typical Cost in UAE |

$$ |

$$-$$$ |

$$$$ (Premium) |

- |

|

Best For |

Frames, enclosures, marine fittings |

Structural platforms, welded frames, marine |

Aerospace, defense, high-stress machinery |

Niche, high-performance |

Verdict for the UAE Market: Select 7075 T6 plate only if welding is not necessary and your application requires the utmost strength and fatigue performance. It is not a general-purpose improvement; rather, it is specialized stuff.

Corrosion Resistance in the UAE Climate: Protecting Your 7075 T6 Investment

The most important trade-off is this one. Because of its copper component, 7075 T6 has less intrinsic corrosion resistance than alloys from the 6000 family. Unprotected 7075 is prone to pitting and exfoliation corrosion in the harsh, salty environment of the United Arab Emirates.

- Mandatory Protective Finishes: A protective finish is a must for any outdoor or marine application in Dubai, Abu Dhabi, or other coastal regions.

- Recommended Finishes:

- Alodine (Chromate Conversion Coating): Offers a suitable foundation for paint and exceptional resistance to corrosion. Typical in the aerospace industry.

- Hard Anodizing (Type III): Produces a ceramic surface layer that is incredibly hard, resilient to wear, and impervious to corrosion. Perfect for mechanical and military parts.

- Powder Coating: Provides a protective layer that is thick, long-lasting, and aesthetically pleasing for less important applications.

- Professional Painting Systems: Utilizing paints and primers of aeronautical quality.

Top Applications of 7075 T6 Plates in the UAE's Advanced Industries

- Aerospace & Aviation: The main use case. utilized for spacecraft parts, wing spars, landing gear parts, and aircraft fuselage frames that are serviced in MRO (Maintenance, Repair, and Overhaul) facilities located in the United Arab Emirates.

- Defense & Military Technology: Vital to the production of weapon mounts, recoil systems, tactical equipment, and armor plating (both personal and vehicle) for the UAE's cutting-edge defense industry.

- High-Performance Automotive & Racing: Used for gearbox parts, drive shafts, chassis brackets, and specialized suspension parts for race cars and luxury performance automobiles tuned in the United Arab Emirates.

- Precision Machinery & Tooling: Perfect for machine parts, jigs, fixtures, and molds that are subjected to severe stress and need little deflection, such those used in die-casting or plastic injection molding.

- Sports & Mounting Equipment: Used for expensive bicycle parts, rock climbing equipment, and archery equipment when weight reduction and maximum strength are essential.

Machining and Handling 7075 T6 Plate: A Guide for UAE Workshops

- Machinability: One of the greatest aluminum alloys for machining is 7075 T6. In addition to producing clean chips, it enables tight tolerances, high feed rates, and superior surface finishes. It is a "dream to machine" for Sharjah and Dubai's precision workshops.

- Welding (The Major Limitation): Arc welding 7075 T6 is typically regarded as UNWELDABLE. In the heat-affected zone (HAZ), the process results in solidification cracking and a notable loss of strength. Design to be fastened mechanically (bolts, rivets) rather than via welding.

- Heat Treatment: A qualified provider can re-heat treat it to restore T6 characteristics if machining results in stress.

Understanding 7075 T6 Aluminum Plate Pricing in the UAE Market

The premium performance of 7075 T6 comes at a premium cost. Key factors influencing its price in the UAE include:

- Alloying Elements: It costs more to create than other aluminum grades because of its high zinc, magnesium, and copper content.

- Heat Treatment: Significant value and expense are added by the exact T6 tempering procedure.

- Import Source & Quality: The cost of aerospace-grade material from reliable foreign mills (such as those in the USA or Europe) is greater.

- Thickness & Form: More expensive are thicker plates and particular tempers (such as T651).

- Quantity & Processing: Per kilogram, full plates are more economical. The ultimate cost is increased by custom cutting, finishing (anodizing/alodining), and strict certification (e.g., MIL-spec).

➤ Owing to its specialized nature, always ask UAE vendors for a written quote that includes the thickness, dimensions, temper (T6/T651), and other certificates.

Frequently Asked Questions (FAQ) About 7075 T6 Plates

Is 7075 T6 the strongest aluminum plate available?

Indeed. Everyone agrees that 7075 in the T6 temper is the strongest of the commercially available aluminum alloys in plate form.

Can you weld 7075 T6 aluminum plate? It is strongly discouraged.

Traditional welding techniques seriously weaken the material and cause cracking. Use adhesive bonding or mechanical fasteners, such as rivets or high-strength bolts, if connecting is required. Redesign key structures to eliminate the need for welding.

How does 7075 T6 handle the salty UAE air? Poorly without protection.

Compared to other alloys, it has a lesser intrinsic resistance to corrosion. A strong protective finish, such as hard coat anodizing or alodining, is crucial for any application in the coastal environment of the United Arab Emirates.

Is 7075 T6 plate good for machining? It is excellent for machining.

Compared to many other metals, it is referred to as a free-machining alloy because it permits greater speeds, superior surface finishes, and less tool wear.

What is the difference between 7075 T6 and T651?

After heat treatment, T651 shows that the plate has been stretched to relieve stress. This lowers the possibility of part warping during milling by offering improved dimensional stability. T651 is frequently worth the additional expense for precision components.

Where can I buy certified 7075 T6 plate in the UAE?

Reputable metal suppliers in the UAE that specialize in high-performance alloys and are able to offer complete material certification (MTC) traceable to the mill are the ones you need to work with. For defense and aerospace applications, this is essential to ensure characteristics and validity.

Dimensions: 16mm to 110mm x 1500mm x 3000mm

AA1100 H14 Plates

3003 H14 Plates

5083 H111 Plates

5083 H116 Plates

6082 T6 Plates & Bars

7075 T6 Plates

Disclaimer

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as they become available.