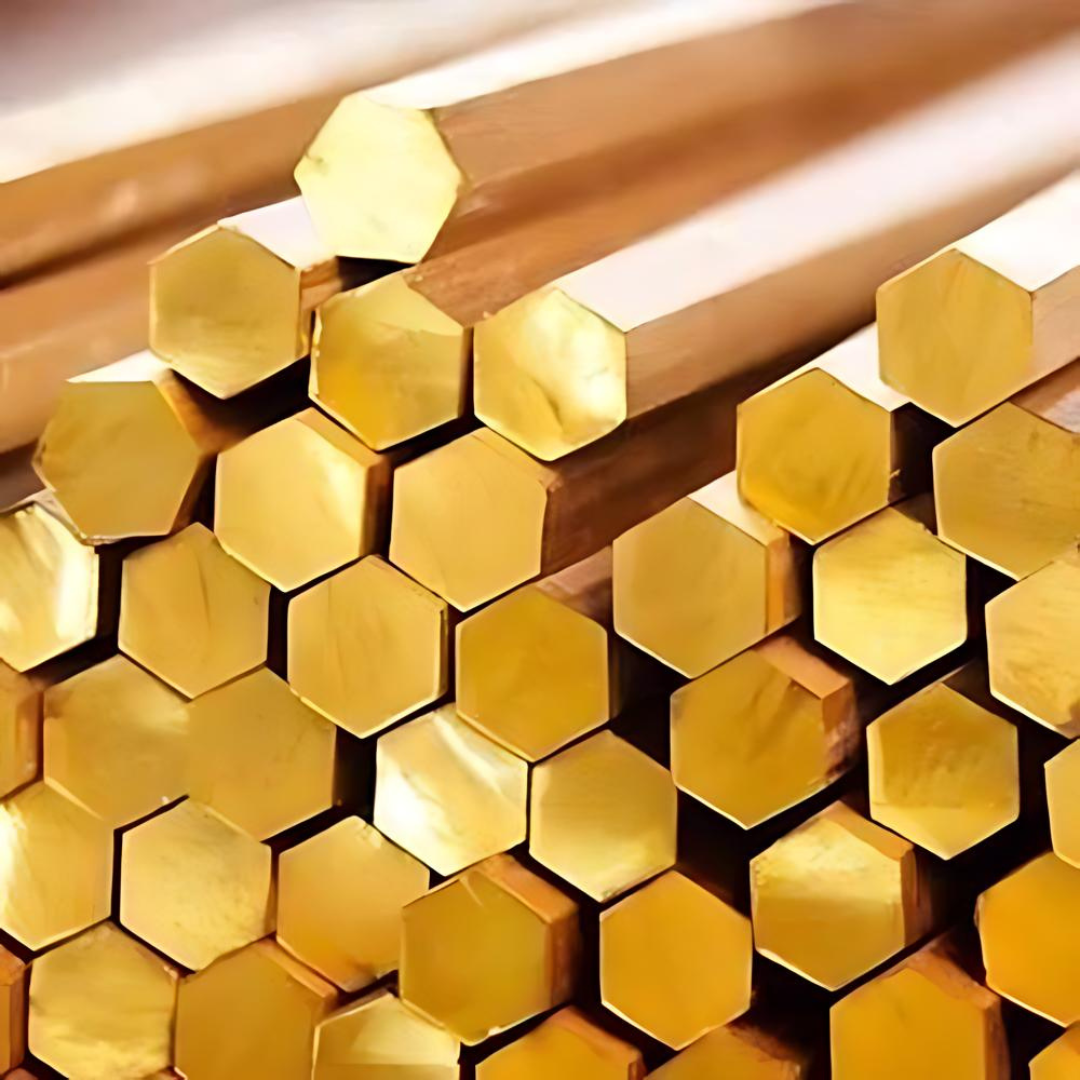

Product Overview

CZ121 offers the highest possible machinability of any copper alloy. This alloy is a free-machining brass with a 3% lead content - this addition of lead is finely dispersed throughout the material microstructure which acts as both a lubricant and chip breaker. This results in giving the alloy its free machining characteristics. With a machinability rating of 100%, CZ121 is the standard by which all other copper-based alloys are rated. The alloy also offers good corrosion resistance and strength.

Alloy Attributes

• Good corrosion resistance

• Easily soldered or brazed

• Good strength

• Highest machinability of any copper alloy

Related Material Specifications

• C38500 • CW614N • BS2874

• 2.0401 • NF A51-105 • CuZn39Pb3

• CuZn40Pb3 (FR)

Weldability

Soldering - Excellent

Brazing - Good

Oxy-acetylene welding - Not Recommended

Gas-shielded arc welding - Not Recommended

Resistance welding: Spot & Seam - Not Recommended

Butt - Less suitable

TYPICAL APPLICATIONS

• All types of machined components

• Fasteners

• Extruded sections

• Window frames

• Plug pins

• Switch blocks

Material: Brass

Dimensions:

16mm to 65mm

Disclaimer

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as they become available.