Aluminum Coil

Product Overview

Hidayath Aluminum Coils — Which Alloy Fits Your Job?

AA1100 - Commercial Grade

Lightweight, excellent corrosion resistance, and easy formability.

-

Thickness: 0.2 – 6.0 mm

-

Width: 600 – 1600 mm

-

Applications: Roofing, siding, cladding, packaging, decorative use.

3003 - Manganese Alloy

Stronger than AA1100 with excellent resistance to atmospheric corrosion.

-

Thickness: 0.3 – 6.0 mm

-

Width: 1000 – 1500 mm

-

Applications: Insulation jackets, ducting, signage, general fabrication.

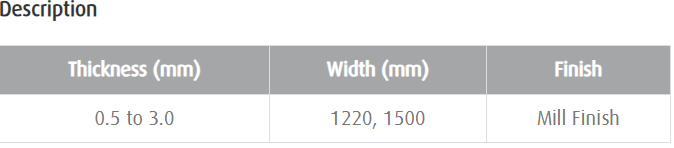

5052 / 5754 - Medium Strength Alloys

Good corrosion resistance, weldable, higher strength than 3003.

-

Thickness: 0.5 – 6.0 mm

-

Width: 1000 – 1600 mm

-

Applications: Marine panels, fuel tanks, transport, architectural cladding.

5083 - Marine Grade Alloy

Exceptional corrosion resistance in seawater and chemical environments.

-

Thickness: 1.0 – 8.0 mm

-

Width: 1000 – 1500 mm

-

Applications: Shipbuilding, offshore platforms, marine walkways, cryogenic tanks.

6082 T6 - High Strength Structural Alloy

High tensile strength, good machinability, and weldable in certain conditions.

-

Thickness: 2.0 – 150 mm

-

Width: 1000 – 1500 mm

-

Applications: Heavy-duty flooring, ramps, truck bodies, structural panels.

7075 T6 - Aerospace Grade Alloy

Ultra-high strength, lightweight, with lower corrosion resistance than marine alloys.

-

Thickness: 10 – 200 mm

-

Width: 1000 – 1500 mm

-

Density: 2.81 g/cm³

-

Applications: Aerospace, defense, high-load structures, specialty engineering.

Which Finish Matches Your Look?

At Hidayath, we understand that every project demands a specific surface finish. That’s why our aluminum coils are available in a wide selection of treatments to match your application:

-

Mill Finish:

The natural as-rolled surface, suitable for general industrial and fabrication use.

-

Bright Finish:

Highly reflective and smooth. Ideal for architectural and decorative projects that demand visual appeal.

-

Anodized Finish:

Electrochemically treated for enhanced corrosion resistance and durability in demanding environments.

-

Color-Coated Coils:

Pre-painted coils available in a range of shades for roofing, cladding, and signage applications.

-

Protective Film Options:

To safeguard sensitive or polished surfaces during handling, fabrication, and installation.

By offering these finishes, we ensure that our coils are not just functional but also enhance the aesthetics and lifespan of your projects.

Where Will These Coils Work Best?

Hidayath aluminum coils are designed to serve multiple industries and applications across the UAE and beyond:

-

Industrial & Structural:

Durable enough for ducting, insulation jackets, machinery covers, and factory cladding.

-

Marine & Offshore:

With marine-grade alloys like 5083, our coils are trusted for shipbuilding, docks, and offshore structures where saltwater resistance is critical.

-

Transport & Automotive:

Lightweight yet strong. Aluminum coils are widely used in truck bodies, trailers, bus panels, and other transportation components.

-

Architectural & Decorative:

From roofing and façades to ceilings and signage. Our coils offer both strength and aesthetic value.

-

Commercial & Packaging:

Thin-gauge coils are ideal for packaging, container manufacturing, and display fixtures.

Wherever durability, corrosion resistance, and formability are required, Hidayath aluminum coils provide proven performance.

Custom Supply & Services

Every project has its own set of requirements, and at Hidayath we take pride in delivering tailor-made solutions:

-

Slitting & Coil-to-Coil Conversion: We can slit coils to your exact width for downstream processing.

-

Cut-to-Length Sheets: Our facilities allow us to supply coils as ready-to-use flat sheets in custom dimensions.

-

Surface Protection & Coatings: Optional lamination and protective films keep your material safe until installation.

-

Flexible Coil Weights: Whether you need lightweight coils for easy handling or heavy coils for large-scale production, we adjust supply as per your need.

-

Local & Export Supply: With a strong distribution network in the UAE and GCC, we ensure reliable delivery for both domestic and international clients.

By combining a wide range of alloys with precision processing services, Hidayath ensures that every coil we supply adds real value to your project.

Frequently Asked Questions (FAQs) on Hidayath Aluminum Coils

Can I get aluminum coils in custom widths or cut-to-length sheets?

Yes. Coils can be slit to your required width or converted into sheets with custom lengths and surface finishes.

Which aluminum coil grade should I choose for marine applications?

For coastal and offshore use, 5083 marine-grade aluminum is ideal. Due to its superior corrosion resistance in seawater environments.

What is the maximum coil weight Hidayath can supply?

Coils are typically available from 1–5 tonnes per roll, depending on thickness and width. Heavier or lighter coils can be arranged on request.

Can I order aluminum coils in UAE for export?

Absolutely. Hidayath supplies to projects across the UAE and ships internationally. Ensuring timely delivery with export-grade packaging.