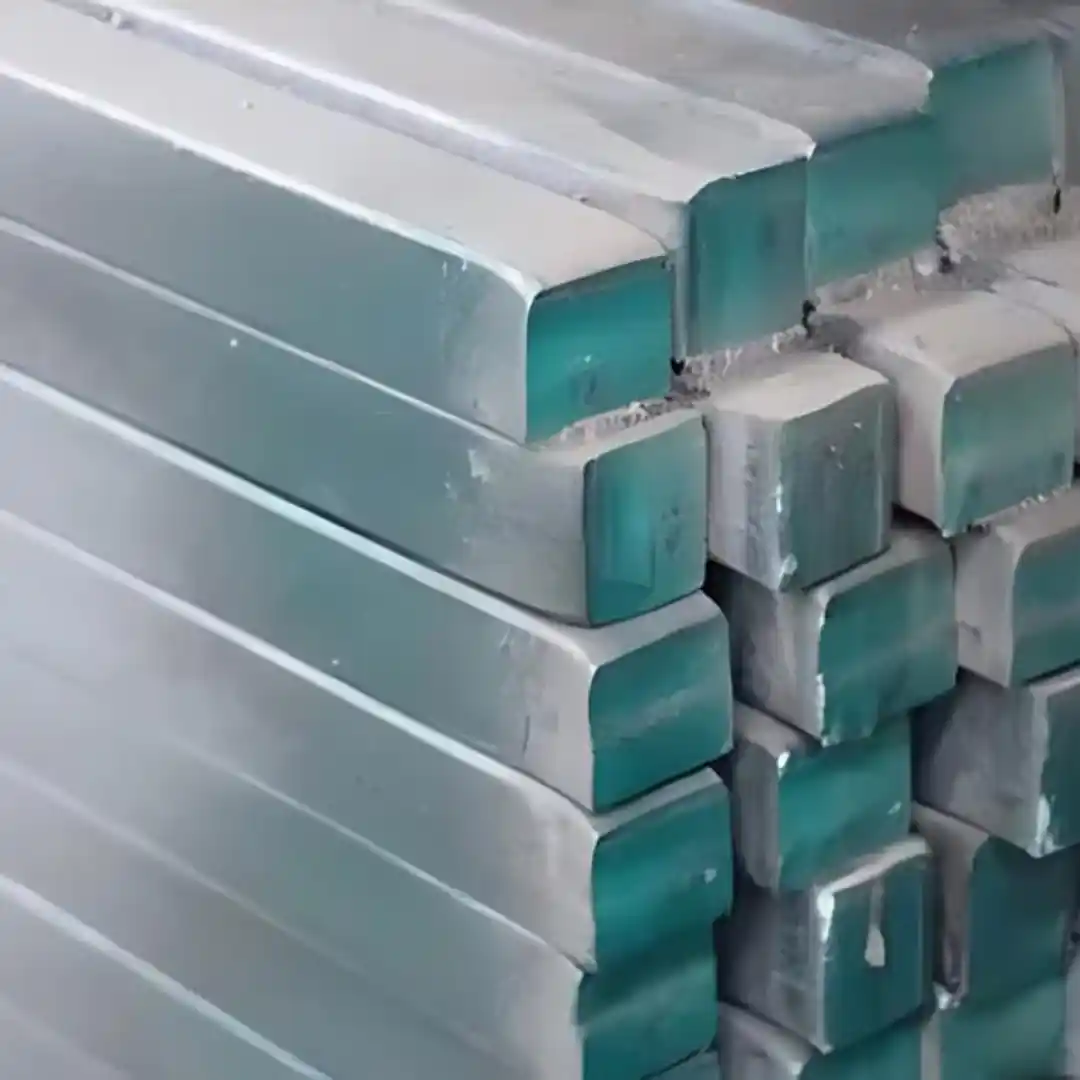

Product Overview

EN8 Square Bars: All About EN8 Square Bars for UAE Engineers, Fabricators, and Buyers

In the tough industrial environment of the United Arab Emirates, EN8 Square Bars are the material of choice when your project calls for greater strength than mild steel without requiring all the qualities of a high-alloy grade. This comprehensive pointer helps you choose the best, most affordable option for your application by covering everything from local sourcing and price in the UAE to its technical specifications and best finishes.

What Exactly is EN8 Square Bar? Definition, Grades, and Equivalents

A common and adaptable medium carbon steel square bar is EN8 Square Bar (BS 970 Standard). It is the dependable workhorse of the engineering sector, known for its exceptional tensile strength and great machinability.

- Other Names/Equivalents: Engineers and importers in the UAE must be aware that EN8 Square Bar is also referred to as 080M40 (UK), 1040 (AISI/SAE USA), and C40 (EU/DIN). For the majority of tasks, these grades can be used interchangeably because of their nearly identical chemical makeup. Because of this, vendors frequently list it as "EN8/1040 Square Bar."

What are EN8 Square Bar Technical Specifications & Available Sizes in the UAE?

Projects based in the UAE need accurate information. The qualities of EN8 square bars and the common sizes that are easily obtained from UAE stockists are broken down here.

|

Property |

Details & Specifications for UAE Projects |

|

Standard Sizes |

10mm, 12mm, 16mm, 20mm, 25mm, 32mm, 40mm, 50mm, 65mm, 80mm, 100mm. (Custom cutting to length is a standard service in the UAE). |

|

Available Conditions |

Black (Hot-Rolled), Bright Drawn (Cold-Drawn), Turned, Precision Ground. |

|

Key Grades |

EN8 Square Bar / 080M40 / 1040 Carbon Steel |

|

Typical Hardness (as supplied) |

201-255 Brinell (HB). Can be heat treated to 500-600 HB for extreme wear resistance. |

|

Tensile Strength |

510 - 700 MPa (As rolled/Normalized). Increases significantly after heat treatment. |

|

Chemical Composition |

Carbon (C): 0.36%-0.44%, Manganese (Mn): 0.60%-1.00%, Silicon (Si): 0.10%-0.40% |

|

Common Finishes |

As-supplied (Black with mill scale), Bright Drawn (smooth, clean), Precision Ground (for tight tolerances). |

Bright Drawn vs. Black EN8 Square Bar: Which Is the Right Finish to Choose for Your UAE Application?

The final application, machining time, and cost are all greatly impacted by the finish you choose.

Bright Drawn EN8 Square Bar

A cold-finished bar with a smooth, scale-free surface and exact dimensional tolerances. The final machining effort is reduced with this finish.

- Best for: CNC machining jobs when tool life is crucial, precision shafts, pins, bolts, and completed components where beauty matters.

- UAE Context: Perfect for expensive machining operations in the industrial zones of Abu Dhabi and Dubai Sharjah, where productivity and quality are crucial.

Black EN8 Square Bar (Hot-Rolled)

A darker, oxidized mill scale surface that is more cost-effective. It is ideal in situations when surface polish is not a top concern, although it does require extra machining allowance.

- Best for: Structural components, heavy-duty brackets, frames, jigs, fixtures, and general fabrication that will all be fully machined.

- UAE Context: The preferred option for industrial, heavy fabrication, and large-scale construction projects in the United Arab Emirates where cost-effectiveness on non-critical surfaces is crucial.

Maximizing Performance: Can EN8 Square Bar Be Heat Treated?

EN8 Square Bar performs better than mild steel in this situation. Engineers in the UAE must comprehend heat treatment.

- As-Supplied (Normalized): It is usually delivered in this condition, ready for use right out of the source, and offers a wonderful mix between strength (200–250 BHN) and machinability.

- Heat Treated EN8 Square Bar (Hardened & Tempered): EN8 Square Bar reacts to tempering and quenching very well.

- Hardened EN8: Can be hardened to a substantially higher strength (usually 500–600 BHN), which significantly boosts its load-bearing capability and resistance to wear.

- Tempering: Tempering is used to provide the precise hardness needed for the application and lessen brittleness after hardening.

- UAE Supplier Tip: Many leading UAE steel stockists offer in-house or partnered heat treatment services. In-house or partner heat treating services are provided by numerous top steel stockists in the United Arab Emirates. EN8 square bars can frequently be found pre-hardened to your precise requirements (such as EN8D), which will save you time and logistical trouble.

EN8 vs. Mild Steel (EN3/EN1A): Why Upgrade for Your UAE Project?

This is a critical decision for cost and performance. Here’s why you might choose EN8:

|

Feature |

Mild Steel (e.g., EN3) |

EN8 Medium Carbon Steel |

|

Carbon Content |

Low (0.1-0.3%) |

Medium (0.36-0.44%) |

|

Tensile Strength |

Lower (~400-500 MPa) |

Higher (510-700 MPa) |

|

Hardness |

Softer (~130 BHN) |

Harder (200-255 BHN) |

|

Wear Resistance |

Poor |

Good (Excellent when hardened) |

|

Machinability |

Good |

Very Good to Excellent |

|

Cost |

Slightly Lower |

Slightly Higher |

|

Best For |

Basic structures, non-critical parts |

Stressed parts, shafts, gears, axles |

Verdict: Choose EN8 when your component will face higher stress, friction, or load and requires greater durability without the cost of an alloy steel.

What are the Top Applications of EN8 Square Bars in the UAE Industry?

When your component is subjected to increased stress, friction, or load and needs more durability without incurring the expense of an alloy steel, go with EN8.

- General Engineering & Machining: Because of its exceptional machinability, it is the first choice for premium shafts, gears, bolts, pins, and axles.

- Automotive & Transportation: Utilized in the production of crankshafts, axle shafts, and spindles for heavy machinery and vehicles that are frequently found in the construction and logistics industries in the United Arab Emirates.

- Construction & Heavy Fabrication: Vital for specialized brackets, jigs, fittings, and high-strength structural frames that must endure the severe weather and heavy loads of infrastructure projects in the United Arab Emirates.

- Tooling & Machinery: A strong and affordable material for clamps, vices, non-cutting tools, and machine parts that need to withstand wear.

- Marine & Offshore (With Proper Coating): When combined with the proper protective coatings and maintenance plans, EN8—which is not stainless—is utilized for some non-corrosive environmental components on ships and rigs.

What are EN8 Square Bar Price Factors in the UAE Market?

Several important factors affect EN8 square bar prices in the United Arab Emirates:

- Global Steel Prices: Varies according to the price of raw materials and global demand.

- Size and Length: Longer lengths and larger cross-sections are more expensive.

- Finish: Bright drawn EN8 is more costly than black EN8 bars because it requires more processing.

- Quantity: The pricing per meter/kg is usually much lower for bulk orders (whole bundles or tons).

- Additional Processing: Although they cost more, services like precision grinding, heat treatment, and cutting-to-size reduce the amount of time you need for internal processing.

- Logistics: Delivery charges may be impacted by the supplier's location inside the United Arab Emirates, such as Dubai, Sharjah, or Abu Dhabi.

➤ Always ask for a quote based on your unique needs for the most precise and affordable EN8 square bar price in the United Arab Emirates.

Frequently Asked Questions (FAQ) About EN8 Square Bars

What is the hardness of a standard EN8 square bar?

The normalized Brinell hardness of EN8 is normally in the range of 201-255 HB.

Can UAE suppliers provide EN8 square bar cut to size?

Yes, precision cutting to your precise length requirements is available from almost all of the main steel stockists in the United Arab Emirates. By doing this, you reduce waste and save your workshop a significant amount of time and money.

Is EN8 suitable for making cutting tools?

It is not the best for cutting tools, but it works well for general-purpose tools like fixtures, jigs, and vices. Alloy steels like EN19 or EN24 or higher carbon steels like EN9 or EN45 are recommended for tools that need a sharp cutting edge.

How does EN8 compare to EN9 steel?

Because EN9 contains more carbon (0.50-0.60%) than EN8, it can harden more thoroughly than EN8. Although it is marginally less machinable, it has superior wear resistance. For applications where the highest level of surface hardness is required, select EN9.

Do UAE suppliers stock heat-treat EN8 square bar?

A lot of people do. Pre-hardened and tempered (HT) EN8 square bars, also known as EN8D, are widely available. When asking, always be specific about the hardness range you need.

Is EN8 steel corrosion resistant?

No, EN8 is prone to corrosion and rust like the majority of carbon steels. Proper protective measures, such as painting, powder coating, or galvanizing, are necessary for use in the humid, coastal climate of the United Arab Emirates. Think about stainless steel grades for their natural resistance to corrosion.

6082 T6 Aluminum Plates: The Premier Choice for High-Strength UAE Applications

One aluminum alloy, 6082 T6 Plate, stands out at the center of the UAE's major engineering and construction projects where strength, weldability, and corrosion resistance are essential. This comprehensive book explores its properties, benefits over alternative alloys, and crucial uses, establishing it as the best material for harsh settings like the offshore platforms in the Arabian Gulf and the towers of Dubai.

What is 6082 T6 Aluminum Plate? The "Structural Powerhouse" Alloy

Of the aluminum-magnesium-silicon alloys in the 6000 series, 6082 has the highest strength. To get its maximum strength characteristics, the "T6" designation indicates that it has undergone solution heat treatment and artificial aging. Because of this method, it is stronger than regular 6061 and has an outstanding strength-to-weight ratio, making it ideal for UAE modern engineering.

6082 T6 Plate Technical Specifications & Available Sizes in the UAE

To satisfy a variety of industrial demands, UAE suppliers usually have a large assortment of sizes in stock. A comprehensive table of properties and standard availability can be seen below.

|

Property |

Details & Specifications for UAE Engineers |

|

Standard Plate Thickness |

3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm+ (Custom cutting is widely available) |

|

Standard Sheet Sizes |

1250x2500mm, 1500x3000mm, 2000x4000mm (Other sizes available on request) |

|

Temper |

T6 (Solution Heat Treated and Artificially Aged) |

|

Yield Strength (Rp0.2) |

≥ 260 MPa - This high yield strength is its key advantage, meaning it resists permanent deformation under high stress. |

|

Tensile Strength (Rm) |

310 - 350 MPa |

|

Elongation (A5) |

≈ 10% |

|

Brinell Hardness (HB) |

≈ 95 HB |

|

Chemical Composition |

Silicon (Si): 0.7-1.3%, Magnesium (Mg): 0.6-1.2%, Manganese (Mn): 0.4-1.0%, Chromium (Cr): ≤ 0.25% |

|

Common Finishes |

Mill Finish, Anodized (Architectural & Hard), Powder Coated, Brushed |

6082 T6 vs. 6061 T6: Which Aluminum Alloy is Right for Your UAE Project?

For engineers and purchasers in the United Arab Emirates, this is the most important comparison. Although both are outstanding, the 6082 T6 frequently performs better.

|

Feature |

6061 T6 Aluminum |

6082 T6 Aluminum |

Winner for UAE Use |

|

Yield Strength |

240 MPa |

≥ 260 MPa |

6082 T6 |

|

Tensile Strength |

290 MPa |

310 MPa |

6082 T6 |

|

Corrosion Resistance |

Very Good |

Excellent (Similar, very high) |

Tie |

|

Weldability |

Excellent |

Excellent |

Tie |

|

Machinability |

Good |

Good (Can produce smoother finishes) |

Tie / Slight edge to 6082 |

|

Anodizing Quality |

Good |

Excellent (Superior surface finish post-anodizing) |

6082 T6 |

|

Extrusion Ability |

Excellent |

Good (But plate form is its strength) |

6061 for complex extrusions |

|

Typical Use |

General purpose frames, truck bodies, pipes |

High-stress structures, marine, military, platforms |

6082 for high-load applications |

Conclusion for the UAE Market: If maximum structural integrity, increased load-bearing capacity, and exceptional performance in challenging conditions are your top priorities, go for 6082 T6 plate. It is without a doubt the best option for important applications.

Why 6082 T6 is the Ideal Aluminum Plate for the UAE's Harsh Climate

Extreme heat, high humidity, and salty coastal air in the United Arab Emirates necessitate materials that are resistant to deterioration. Here, 6082 T6 shines:

- Superior Corrosion Resistance: Because of its exceptional resistance to marine and atmospheric corrosion, it is a top choice for projects in coastal towns like Sharjah, Abu Dhabi, and Dubai.

- High-Temperature Stability: Although all aluminum alloys lose strength at high temperatures, its T6 temper provides good stability in the UAE sun when compared to other rust-prone metals.

- Perfect for Protective Finishes: Its superior surface quality makes it perfect for powder painting and anodizing, which increases its endurance and visual appeal. Anodizing is an extremely strong, corrosion-resistant finish that is frequently used in architecture.

Top 5 Applications of 6082 T6 Plates in UAE Industries

- Marine & Offshore Construction: Throughout the Arabian Gulf, it is the preferred material for boat hulls, decks, superstructures, gangways, and offshore platform components due to its exceptional strength and resistance to corrosion.

- Advanced Transportation: Utilized in the construction of military vehicles, heavy-duty vehicle chassis, body panels, and marine transport vessels when it is essential to reduce weight without compromising strength.

- Architectural & Construction Glazing: The go-to option for architectural frameworks, curtain wall supports, and high-strength structural glazing systems on famous skyscrapers in the United Arab Emirates. One significant benefit is that it may be exquisitely anodized.

- High-Stress Structural Fabrications: Perfect for walkways, crane arms, bridges, and access platforms that need a material that is both exceptionally strong and lightweight to support dynamic loads.

- Aerospace & Defense Applications: Utilized in military infrastructure, non-critical aircraft components, and applications where its unique strength and qualities satisfy strict specifications.

Machining, Welding, and Finishing 6082 T6 Plate: A UAE Workshop Guide

- Machining: The 6082 T6 produces good surface finishes and machines well. For best results, use tools with a good rake angle and sharp edges.

- Welding: It is quite amenable to welding with standard methods like MIG (GMAW) and TIG (GTAW). Make use of filler wire 4043 or 5356. It is crucial to remember that welding heat will locally reduce strength by altering the T6 temper in the Heat-Affected Zone (HAZ). Post-weld heat treatment could be taken into consideration for crucial welds.

- Finishing:

- Anodizing: In the UAE, 6082 T6 is well known for its superb anodizing, which produces a superior, consistent, and long-lasting surface ideal for architectural applications.

- Powder Coating: Provides a protective layer that is thick, sturdy, and vibrant.

- Brushing: Provides a contemporary, ornamental look for interior uses.

Understanding 6082 T6 Aluminum Plate Pricing in the UAE Market

The price per kg or per sheet in the UAE is influenced by:

- Global Aluminum Prices: The main cost driver is the price of aluminum globally (LME rates).

- Thickness and Dimensions: Larger sheets and thicker plates are more expensive.

- Quantity: Compared to small, cut-to-size pieces, full-size plates and bulk orders are substantially less expensive per kilogram.

- Finish: A normal mill finish is used. Precision-machined, powder-coated, or anodized plates are more expensive.

- Supplier Margins & Logistics: Compared to importing small amounts directly, sourcing from a big UAE stockist with local warehouses in Jebel Ali or Mussafah frequently offers better pricing and faster delivery.

➤ For the most accurate 6082 T6 plate price in Dubai, Abu Dhabi, or across the UAE, request a formal quote specifying thickness, size, quantity, and finish.

Frequently Asked Questions (FAQ) About 6082 T6 Plates

Is 6082 T6 aluminum stronger than 6061 T6?

Indeed. The stronger material is 6082 T6, which has a greater tensile strength (310 MPa vs. 290 MPa) and minimum yield strength (260 MPa vs. 240 MPa).

Can 6082 T6 be used in marine environments?

Of course. Because of its exceptional resistance to corrosion, it is regarded as a marine-grade aluminum. It is frequently used in offshore construction and boat building, particularly when combined with the proper marine-grade alloys for fasteners.

How does the price of 6082 T6 compare to 6061 T6 plate in the UAE?

Generally speaking, 6082 T6 is slightly more expensive than 6061 T6 because of its superior strength characteristics and production method. For structural applications, however, the performance advantages frequently outweigh the cost difference.

Is 6082 T6 plate good for welding?

Indeed, it has a stellar reputation for weldability. But be advised that the heat-affected zone (HAZ) will be weakened by welding. Design must take this into consideration for vital structures, or post-weld heat treatment should be taken into mind.

Do UAE suppliers offer custom cutting of 6082 T6 plates?

This is a standard service, indeed. To save waste and fabrication time in your workshop, most major suppliers in Dubai and Abu Dhabi offer precision cutting (waterjet, saw cutting, shearing) to your exact specifications.

Can 6082 T6 be anodized? Yes, and it is one of the best alloys for anodizing.

It is a popular option for architectural cladding and fittings because it creates a superior, consistent, long-lasting anodic covering that is both aesthetically beautiful and protective.

Dimensions: 25mm to 200mm x 3000-5800mm

Finish:

Hot Rolled + Black Surface + UT C/c