Coil to Coil Punching

Product Overview

The most common method of perforating metal uses a rotary pinned perforation roller. This is a large cylinder with sharp, pointed needles on the outside to punch holes into the metal. As the sheet metal is run across the perforation roller, it rotates, continuously punching holes in the passing sheet. The needles on the roller, which can produce a wide variety of hole sizes, are sometimes heated to simultaneously melt the metal which forms a reinforced ring around the perforation.

Coil-to-Coil Punching Services in UAE (Roll-to-Roll / Strip Punching)

At Hidayath, we focus on coil-to-coil punching services in the UAE, also called roll-to-roll or strip punching. Our advanced punching lines provide precise hole patterns, fast throughput, and low material waste. This makes them perfect for industries needing consistency and quality.

With our in-house expertise and modern equipment, Hidayath guarantees tight tolerances, cost efficiency, and on-time delivery for clients in Dubai, Abu Dhabi, Sharjah, and the wider GCC.

Why Choose Hidayath?

In-house coil processing facilities

Ability to handle multiple coil widths, thicknesses, and materials

Protective film application and finishing options

Trusted by HVAC, automotive, construction, and industrial sectors

Stainless Steel Coil Punching (304/316)

Hidayath provides specialized coil punching for stainless steel coils (grades 304 and 316). We serve industries that need durability, corrosion resistance, and precision.

Our applications cover HVAC fins, industrial enclosures, cable trays, filtration systems, and food-grade equipment. Our coil punching services guarantee burr-free finishes and consistent quality for high-volume runs.

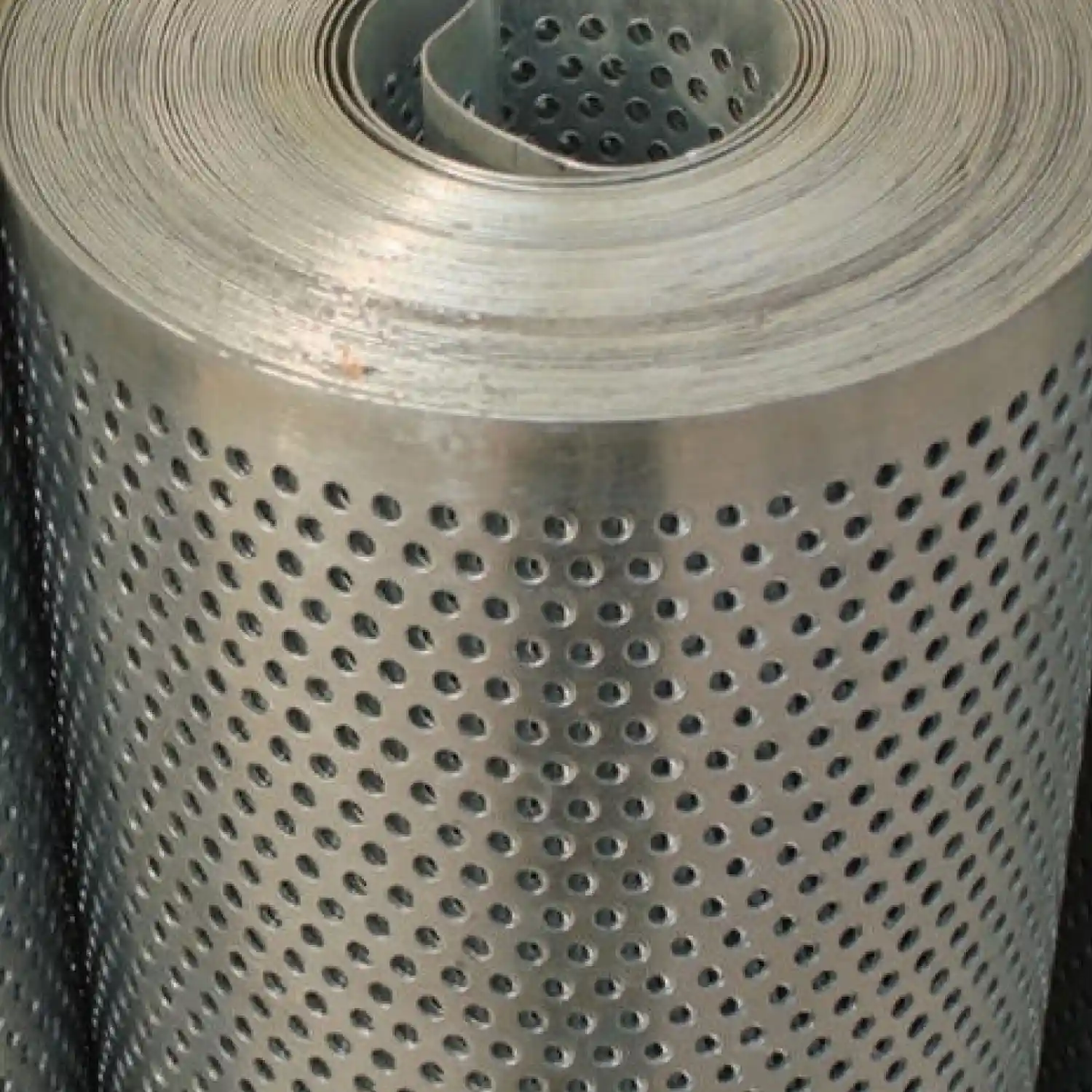

Aluminum and Galvanized Coil Punching

We offer coil punching for aluminum and galvanized steel. This is great for projects needing lightweight strength and corrosion resistance.

Aluminum coil punching is common in solar racking, lighting, electrical enclosures, and ventilation.

Galvanized coil punching is favored in construction, ducting, automotive brackets, and support systems.

Our high-speed punching lines provide quick turnaround, reduce scrap, and ensure accuracy to keep your projects on track.

Copper/Brass Strip Punching

Hidayath offers precision punching for copper and brass strips. We serve electrical, decorative, and industrial applications.

Our punching is ideal for busbars, electrical connectors, trims, and architectural features. It ensures smooth edges, great conductivity, and precise aesthetics.

We handle soft metals carefully to prevent deformation while keeping dimensions exact and consistent.

Hole Patterns & Libraries

At Hidayath, we maintain an extensive hole pattern library for coil punching. Clients can choose from standard designs or request custom tooling to match project needs.

Available patterns include:

Round holes – for ventilation, HVAC fins, and filters

Slot holes – for cable trays, lighting strips, and racking

Oblong holes – for automotive and adjustable parts

Hexagonal perforations – for architectural and filtration solutions

Custom logos and branding patterns – unique die-punched designs for identity and differentiation

Round, Slot, Oblong, Hex, Custom Logos

Our coil punching services allow complete flexibility in design, whether you need standardized industrial patterns or customized brand logos.

By leveraging Hidayath’s advanced punching technology, manufacturers can achieve:

High-speed production with minimal downtime

Consistent and accurate hole placement

Reduced material wastage through optimized strip layouts

Custom branding directly punched into coils for long-term visibility